| Teradyne/GenRad | QA Probe Part Number |

| 2280, 2281, 2281a, 2287a 228x ICA (any model), 2283, 2284, 2286, 2287 built after 7/95 TS121, TS124, TS128, TS81, TS84, TS86, TS87 |

100-PLP1541S, 100-PLP1543S, 100-PLP1541S-B or 100-PLP1543S-B |

| Letter | Material | Average Resistance | ||

| P | Nickel silver/ID precious metal clad | < 20 mOhms | ||

| G | Nickel silver/OD gold plated | < 25 mOhms | ||

| N | Nickel silver/No finish | < 45 mOhms |

| Letter | Spring Force | Preload | 0.107 [2.72] Stroke |

Material | Cycle Life @ 0.107 [2.72] Stroke |

| L | Low | 0.7 [20g/0.19N] | 1.5 [43g/0.42N] | SS | 1,000,000 |

| S | Standard | 1.7 [48g/0.47N] | 3.5 [99g/0.97N] | SS | 1,000,000 |

| H | High | 2.2 [62g/0.61N] | 5.5 [156g/1.53N] | MW | 1,000,000 |

| X | Extra | 3.0 [85g/0.83N] | 8.0 [227g/2.22N] | MW | 1,000,000 |

| U | Ultra | 4.5 [128g/1.25N] | 10.0 [283g/2.78N] | MW | 250,000 |

1 Current Rating is affected by spring material and lubrication choice. MW springs and lubrication both have a 120°C operating temperature limit. Use SS springs with no lubrication (-N) for testing up to 204°C. Before using probes near these limits, please refer to Current Carrying Capacity and Operating Temperature Application Notes.

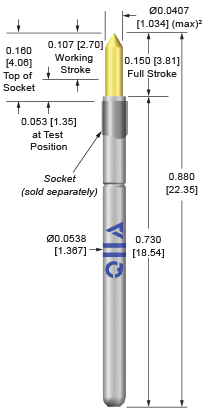

2 Maximum plunger OD should be used to calculate minimum guide plate clearance holes.

3 Working Temperature Range: -55°C to 120°C with lubrication. SS springs can be used up to 204°C without lubrication.

All specifications subject to change without notice. All dimensions are in inches [mm]. All spring forces in ounces [gms].