QA Technology is globally recognized for exceptional product performance, competitive prices, fast delivery and outstanding service.

Our spring loaded test probes and hyperboloid contacts are trusted and specified by the world’s most recognized technology companies and PCB test fixture manufacturers. Our customers know they will produce a higher quality product, meet delivery demands, and achieve higher production yields.

IN-CIRCUIT/FUNCTIONAL (ICT/FCT) TEST PROBES

For in-circuit or functional testing of loaded or bare printed circuit boards.

For higher circuit density; larger probes mounted on closer centers

High conductivity, proprietary metals to carry increased electrical currents.

For use as electromechanical contact between fixture and tester.

DOUBLE ENDED PROBES

For use in testing semiconductor components, such as integrated circuits (IC) and ball grid arrays (BGA).

QA Technology’s high-performance hyperboloid contacts provide a robust and flexible connector system with the flexibility to accommodate standard and custom applications.

QA INTRODUCES Bottom Side Extraction Tool for Damaged Sockets

In applications where pushing a damaged socket through the plate is not feasible, these tools enable socket removal by driving the socket out from the bottom side of the plate (termination end), minimizing damage to the plate and surrounding components.

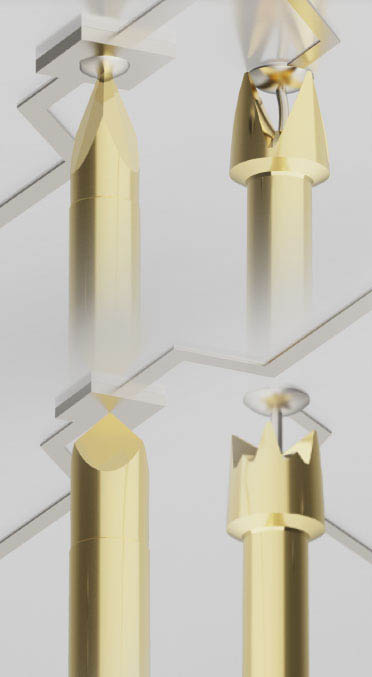

QA INTRODUCES A Reduced Crown Tip Style For 75-mil/X50 Long Stroke Probes

QA’s 54-S reduced crown steel tip style is now available in our 0.400 [10.16] long stroke 075-40 and X50-40 probe series. This tip style is perfect for hitting small diameter targets in dual-level fixtures.

QA INTRODUCES A Reduced Crown Tip Style For 50-mil/X39 Long Stroke Probes

QA’s 14-S reduced crown steel tip style is now available in our 0.400 [10.16] long stroke 050-T40, 050-R40 and X39-40 probe series. This tip style is perfect for hitting small diameter targets in dual-level fixtures.

More Choices with High Preload Spring Forces

QA Technology is pleased to expand our high preload springs offering to include all available probe tube options as well as all steel (-S) tip styles. And what’s even better, we’re reducing our price for the high preload spring probes in these product series. You can now get higher, more consistent spring force with more probe options at a lower price.