Designed for dual level, loaded board testing.

QA Technology offers many combinations of probes. You can build your probe by selecting the tube style, tip style and spring force for your specific application.

If you have questions at any time during the process, contact us at (603) 926-0348.

| Letter | Material | Average Resistance | Current Rating AMPS1 120°C (204°C)4 |

| P | Nickel silver/ID precious metal clad | < 100 milliohms | 2.5 (3.6)4 |

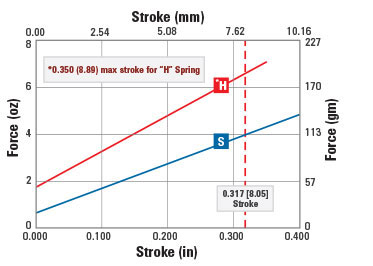

| Letter | Spring Force | Preload | @ 0.317 [8.05] Stroke |

Material | Cycle Life @ 0.317 [8.05] Stroke |

| S | Standard | 0.7 [20g/0.19N] | 4.0 [113g/1.11N] | SS | 50,000 |

| H3 | High | 1.8 [51g/0.50N] | 6.0 [170g/1.67N] | SS | 50,000 |

| Letter | Description |

| N | No probe lubrication. Removing probe lubrication greatly reduces cycle life and should only be used in applications outside of the working temperature range. See Testing in Extreme Working Temperature application note for more details. 4 |

| Heat-treated steel/plated gold over nickel. (see tip styles for availability) |

1 Current Rating is affected by spring material and lubrication choice. Please refer to Current Carrying Capacity and Testing in Extreme Temperature application notes for more details.

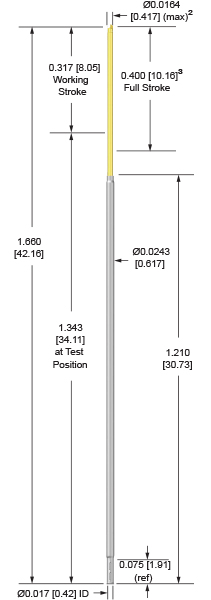

2 Maximum plunger OD should be used to calculate minimum guide plate clearance holes.

3 0.350 [8.89] max stroke for H spring.

4 Working Temperature Range: -45°C to 120°C with lubrication. SS springs can be used up to 204°C without lubrication.

All specifications subject to change without notice. All dimensions are in [mm]. All spring forces are oz [gm/newtons]. US Patent No. 6,570,399 & 4,885,533