Measurement sensitivity is a critical factor when considering probe performance. The more sensitive the measurement, the smaller the threshold between pass and fail, so it is important to match the correct probe to the application.

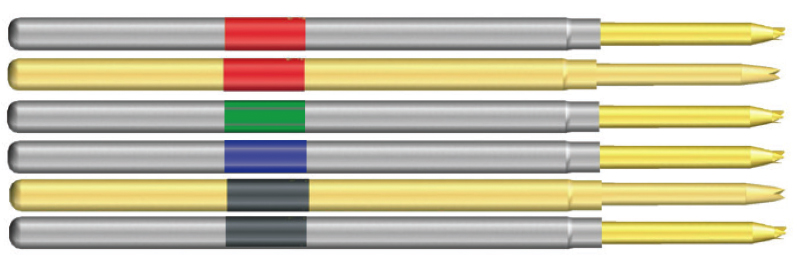

The tube material is an important feature when selecting the right test probe for your application. The following is a summary of the options, characteristics, and color code identification of QA probe tube materials:

The “N” tube is a nickel silver tube without plating. This tube is suitable for bare board test applications or where probe resistance below one ohm is acceptable.

The “G” tube is a nickel silver or phosphor bronze tube plated with gold. This tube is suitable for loaded board and in-circuit testing where an improvement in performance and longer life over the “N” tube is required.

The “V” tube is a nickel silver or phosphor bronze tube plated with silver. This tube is suitable for loaded board and in-circuit testing in non-corrosive environments where an improvement in performance and longer life over the “N” tube is required.

The “P” tube is a nickel silver tube with precious metals clad on the inside surface. This unique cladding process, through deep drawing, hardens the precious metal layer improving wear properties while providing a uniform surface along the entire ID of the tube. This tube is suitable for all loaded board and in-circuit testing where long life and low consistent electrical resistance is required

The “H” tube is a high conductivity proprietary tube plated with gold. This premium tube style is suitable for high current loaded board and in-circuit applications to provide an improvement in performance compared to the “G” and “P” tubes

The “S” tube is a high conductivity proprietary tube plated with silver. This tube style is suitable for high current, loaded board and in-circuit testing applications for use in non-corrosive environments to provide an improvement in performance compared to the “H” tube.