The socket set height is the distance from the top of the probe plate to the top of the socket. Probe performance and longevity are maximized when sockets are installed to the correct set height. When set too low, the probe is under-stroked, reducing the contact force and the probe’s ability to penetrate surface contaminants. When set too high, the probe is over-stroked, which may cause reduced spring life, risk damage to the unit under test (UUT) or incur tip damage due to bottoming. To calculate proper set height, follow these steps:

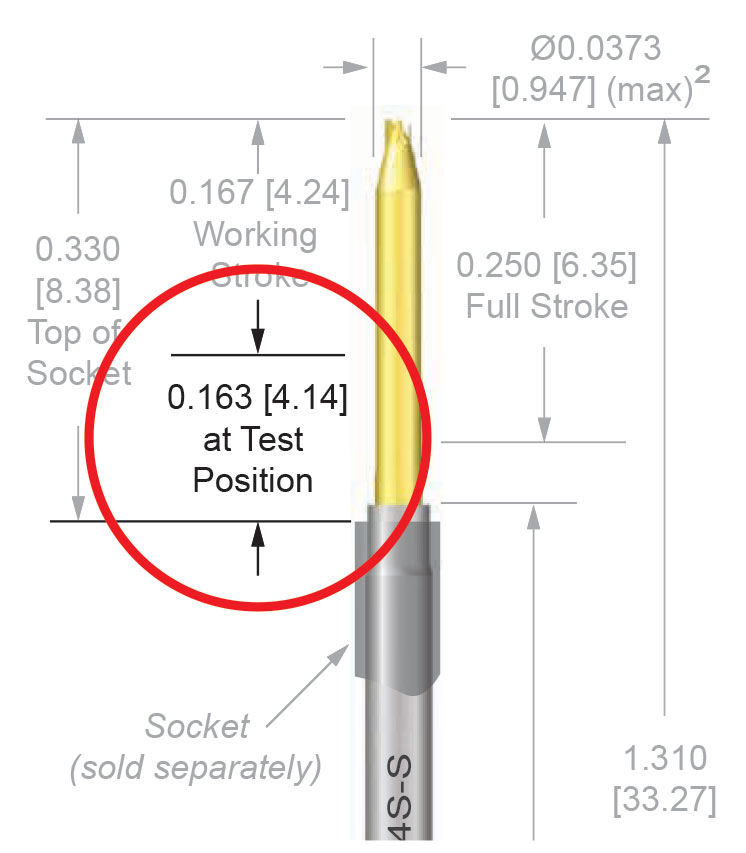

Retrieve dimension (A) “at Test Position” from the product series page from our catalog or website. This is simply the distance from the tip of the probe of an unactuated plunger to the top of the socket, minus the working/test stroke. It is important to note that these dimensions may vary from series to series so a separate calculation must be made for each probe series used in the fixture.

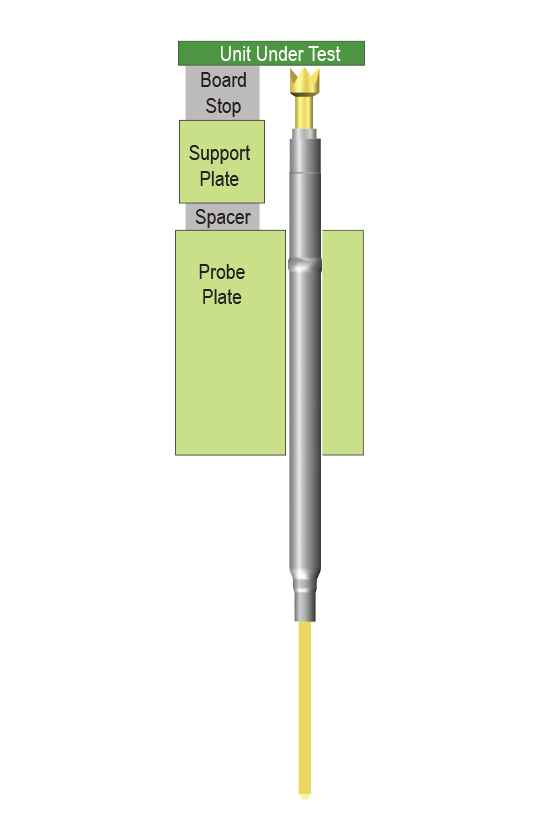

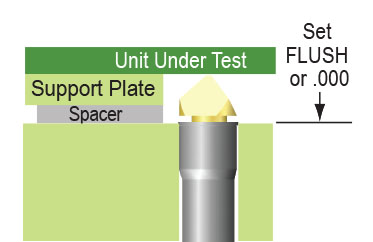

Make a cross-sectional sketch of your fixture in the actuated/test position, including board stops, support plates, spacers, etc. This sketch illustrates one example of a typical fixture.

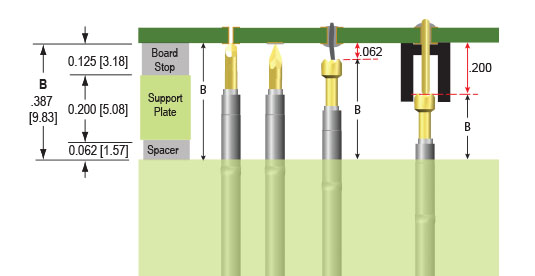

Add the thickness of the items that stack up between the top surface of the probe plate and the contact surface of the UUT to get dimension (B). If contacting leads, posts, or components, subtract the average length of these to adjust dimension (B).

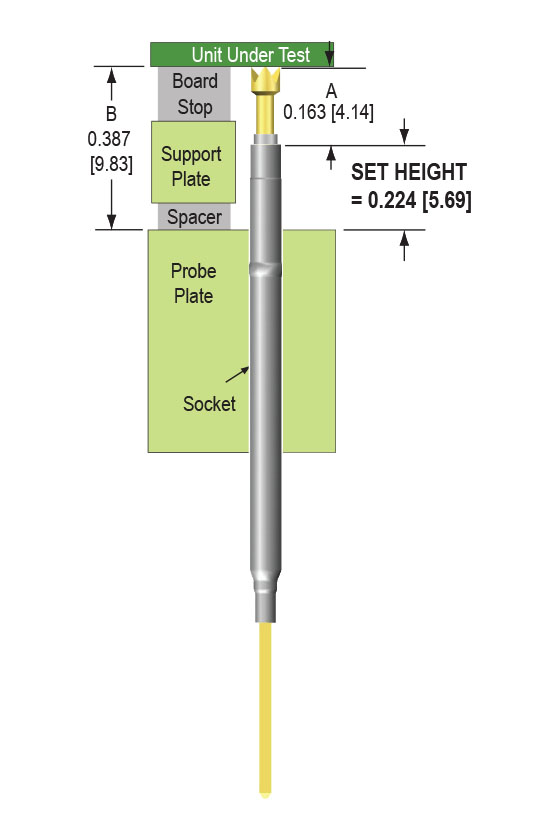

Subtract the at test position dimension (A) from total stack up dimension (B).

Example for 100-25 Series:

You can now use this set height dimension to install your sockets with our ATR adjustable or ITR preset installation tools.

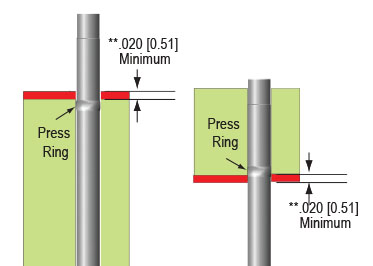

To account for irregularities in the mounting hole, QA recommends a margin of at least 0.020 [0.51] between the press ring and the closest plate surface.

100-05, 050-05, and 025-16 series sockets are all mounted flush (set height is zero).

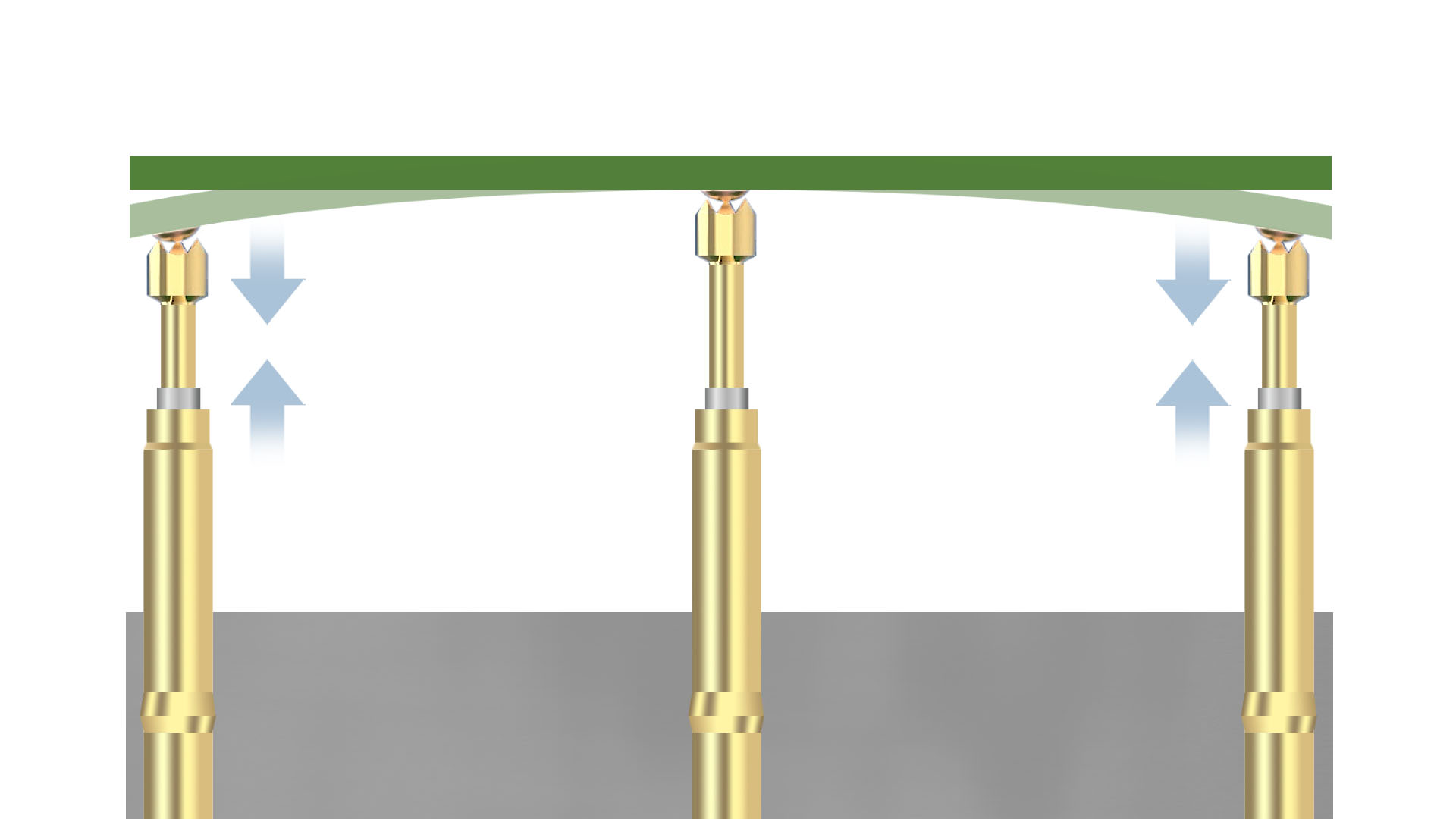

Users should consider board flexing and bowing as they calculate socket set heights. Be sure that all probes are stroked to at least their working stroke.

More details on this can be found in our instructional video on how to calculate socket set heights.